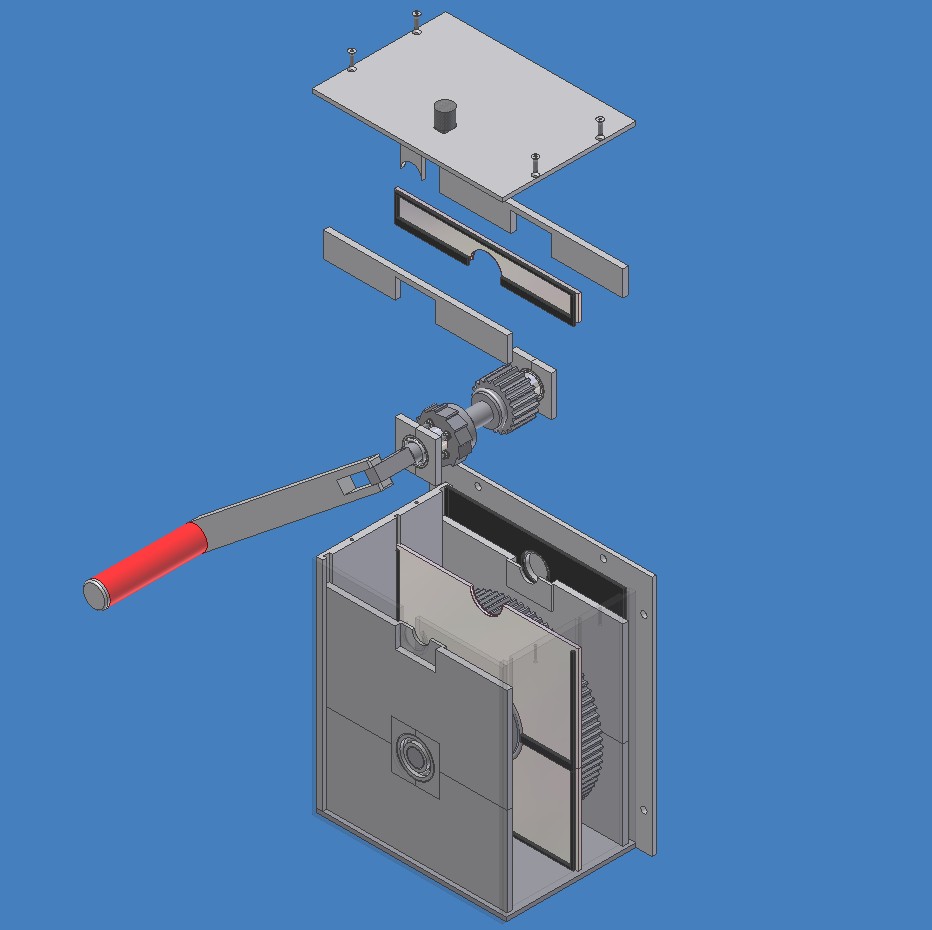

Winch Design

During my second year I only had one design assignment which was to design a safe winch that could raise a load of 75Kg. The full remit of this task has not been published on this site but various views of the winch have been displayed. Like a lot of my project work at Newcastle the work for this project is mainly contained within a log book and so I have explained some of the features of my winch on this page.

The mathematics behind the winch are contained within my project log book and it is this work that determined the size of the winch drum and the gear ratios. The challenging aspects of the winch itself were designing the method of assmby which would allow maintenance, sealing the gears in an lubricant reservoir and bearing location. To make resolve these problems I decided to design a very complex and innovative winch where the case and driveshaft design would eliminate all of the problems.

The assembly of the drum helped to secure the winch wire and the case supported the 2 shafts. Grooves in the side of the case helped to locate sections of Aluminium which locked the bearings in place. The bearings supported the ends of each shaft and so the each shaft could be removed with ease if the case was opened. Seals inside the sections then stopped oil leaking into the rest of the case. This project was graded 60% and soon I will be adding scans of my log book to this page.